PEFC – FSE

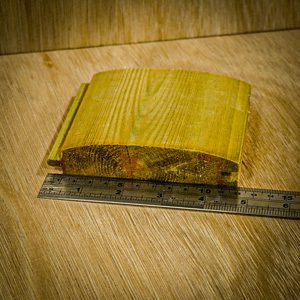

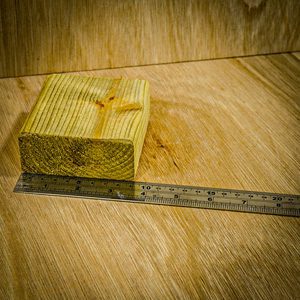

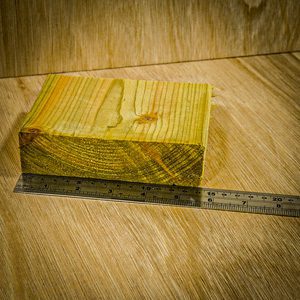

All of the buildings made at our Staffordshire manufacturing facility are produced using timber that is certified by the Forestry Stewardship Council. We are committed to the correct environmental, sustainable and socially beneficial harvesting of the timber we use.